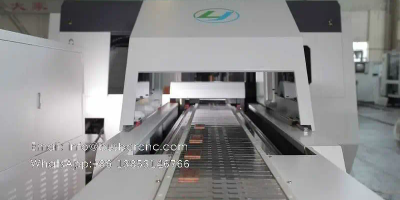

High-efficiency Cutting Machine: The Necessary Equipment to Improve the Efficiency of Busbar Processing

Busbar processing plays a crucial role in the manufacturing and installation of electrical equipment. It involves the fabrication of conductive metal bars that are used to connect electrical components within switchgear, distribution boards, and other power distribution systems. To streamline the busbar processing operations and improve overall efficiency, the use of high-efficiency cutting machines has become indispensable. These advanced machines are designed to enhance precision, speed, and safety in busbar processing, ultimately leading to higher productivity and cost savings for manufacturers. In this article, we will explore the significance of high-efficiency cutting machines in busbar processing and the various benefits they offer to the industry.

Precision Cutting Capabilities

High-efficiency cutting machines are equipped with advanced technologies that enable precise and accurate cutting of busbars. The ability to achieve tight tolerances and clean edges is essential in busbar processing, as it directly impacts the quality of the final electrical connections. By utilizing high-precision cutting machines, manufacturers can ensure that the busbars are cut to the exact specifications required for the specific application, thereby minimizing rework and ensuring consistent quality across production batches.

Enhanced Productivity and Throughput

One of the major advantages of high-efficiency cutting machines is their ability to significantly improve productivity and throughput in busbar processing. These machines are capable of performing rapid and precise cuts, reducing the time required to process each busbar. As a result, manufacturers can increase their overall output and meet tight production schedules more effectively. The high-speed cutting capabilities of these machines contribute to a streamlined manufacturing process, allowing for greater efficiency and output without compromising on quality.

Flexibility in Cutting Operations

Modern high-efficiency cutting machines offer a range of cutting options and configurations to accommodate diverse busbar processing requirements. Whether it’s straight cuts, notches, perforations, or complex shapes, these machines can be programmed to perform a variety of cutting operations with ease. This level of flexibility is invaluable in meeting the evolving demands copper bending machine of the electrical industry, where busbars come in various shapes and sizes to suit different applications. Manufacturers can adapt to changing design specifications and produce customized busbars efficiently, thanks to the versatile cutting capabilities of these machines.

Minimized Material Waste

Efficient utilization of material is a critical consideration in busbar processing, as it directly impacts production costs and environmental sustainability. High-efficiency cutting machines are designed to minimize material waste by optimizing the cutting process, thereby reducing scrap and maximizing the use of raw materials. Through precise nesting and cutting algorithms, these machines help manufacturers minimize material losses and achieve higher material efficiency, leading to cost savings and a reduced environmental footprint.

Improved Operator Safety and Ergonomics

Safety is paramount in any manufacturing environment, and busbar processing is no exception. High-efficiency cutting machines are equipped with safety features and ergonomic design elements to protect operators during the cutting operations. Automated cutting processes reduce the need for manual handling of busbars, minimizing the risk of injuries and repetitive strain on workers. Additionally, modern cutting machines incorporate safety interlocks, guarding, and other measures to ensure a secure working environment, contributing to the overall well-being of the workforce.

Integration with Digital Manufacturing Technologies

The integration of high-efficiency cutting machines with digital manufacturing technologies has revolutionized busbar processing operations. These machines are often equipped with software interfaces that enable seamless integration with computer-aided design (CAD) systems, manufacturing execution systems (MES), and other digital platforms. This integration streamlines the production workflow, allowing for efficient programming, monitoring, and control of the cutting process. Furthermore, it facilitates the adoption of Industry 4.0 principles, paving the way for smart, interconnected manufacturing environments that optimize resource utilization and enable data-driven decision-making.

Cost Savings and Return on Investment

While high-efficiency cutting machines represent a significant upfront investment, they offer substantial long-term cost savings for manufacturers. The enhanced efficiency, productivity, and material utilization provided by these machines translate into tangible financial benefits over time. Reduced labor costs, minimized material waste, and improved throughput contribute to the overall return on investment (ROI) for companies that embrace high-efficiency cutting technologies in their busbar processing operations. Moreover, the ability to meet tight production deadlines and deliver high-quality busbars further enhances the competitiveness and profitability of manufacturers in the electrical industry.

In conclusion, high-efficiency cutting machines have emerged as indispensable equipment in the busbar processing industry, offering a wide array of benefits ranging from precision cutting to improved productivity, flexibility, and cost savings. As the demand for high-quality, custom-designed busbars continues to rise, the adoption of advanced cutting technologies will be instrumental in meeting cnc punching machine the evolving needs of the electrical sector. By investing in high-efficiency cutting machines, manufacturers can elevate their busbar processing capabilities, drive operational excellence, and stay ahead in a competitive market landscape.