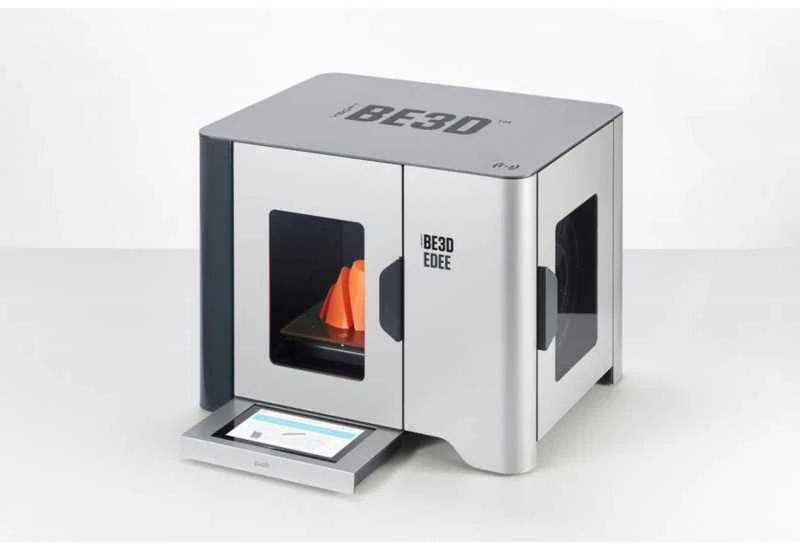

3D printing is a process of creating three-dimensional objects by laying down successive layers of material until the object is formed. In order to 3D print an object, you need to have a digital model of it first. This model can be created using 3D modeling software or downloaded from a file-sharing platform. However, not all file formats are compatible with 3D printing. Let’s dive into the different file formats that are needed for 3D printing.

.STL (STereolithography)

The most common file format used in 3D printing is .STL, which stands for STereolithography. The .STL file format represents the surfaces of a 3D model as triangles. It takes the 3D model and divides it into small triangles called facets. These facets then make up the surface of the object, forming a mesh. The .STL file format is widely used because it is supported by almost all 3D printers and slicing software.

The downside to .STL files is that they do not contain color or texture information. This means that if you want to print an object with multiple colors or textures, you will need to separate the object into different parts and print each part separately.

.OBJ (Object)

Another file format used in 3D printing is .OBJ, which stands for Object. The .OBJ file format is an open standard and is used to store 3D models. Like .STL files, .OBJ files also represent surfaces as triangles. The main advantage of .OBJ files is that they can contain additional information such as color and texture information.

However, the downside of .OBJ files is that they tend to be larger than .STL files. This can cause problems when trying to transfer files between devices or when trying to print large objects.

.AMF (Additive Manufacturing File Format)

The Additive Manufacturing File Format, or .AMF, is a newer file format that is designed specifically for 3D printing. It is an open standard like .OBJ files and contains information about the object’s geometry, color, and material properties.

One of the main advantages of .AMF files is that they can represent objects with curved surfaces more accurately than .STL and .OBJ files. Additionally, .AMF files can contain information about material properties, such as density and melting point. This can be useful when printing objects with specific material requirements.

.GCODE

Once you have your 3D model in a compatible file format, you need to convert it into instructions that your 3D printer can understand. This is done using a slicing software, which converts the 3D model into a series of instructions called GCODE.

GCODE is a programming language that controls the movements of the printer’s extruder and bed. It tells the printer where to move and how much material to extrude. The sliced file, which contains GCODE instructions, is then transferred to the 3D printer, which reads the instructions and prints the object layer by layer.

In conclusion, when it comes to 3D printing, having the right file format is crucial. The most commonly used file formats are .STL, .OBJ, and .AMF. Each file format has its own advantages and disadvantages, so it is important to choose the one that best suits your needs. Finally, remember that regardless of the file format you choose, you need to convert it into GCODE before printing it on your 3D printer.